Cut up uniforms from all branches of the U.S. military, separated by color to maintain the color in the finished paper

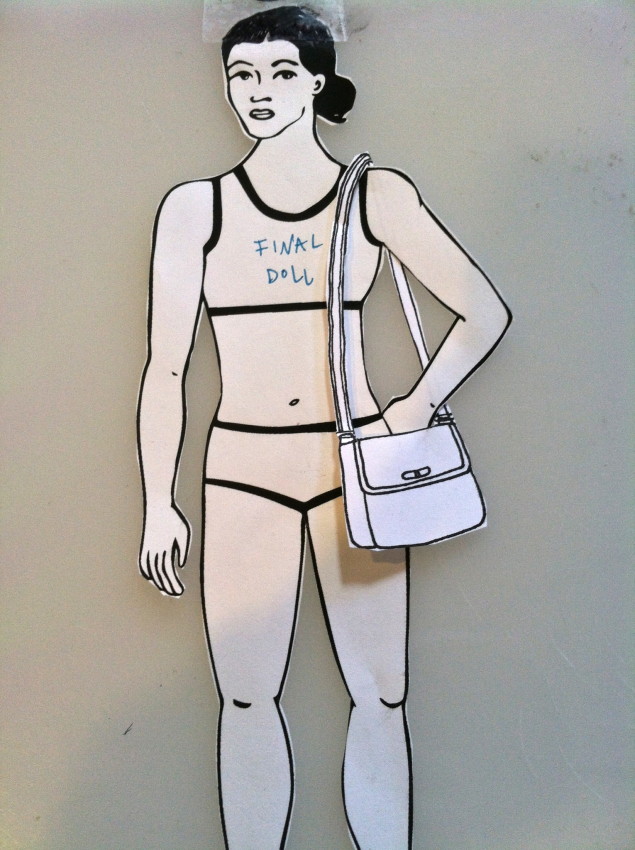

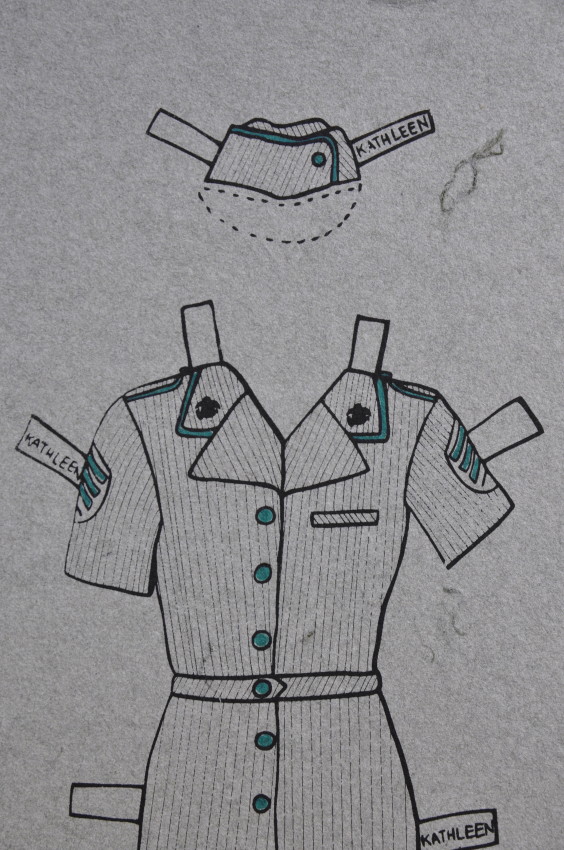

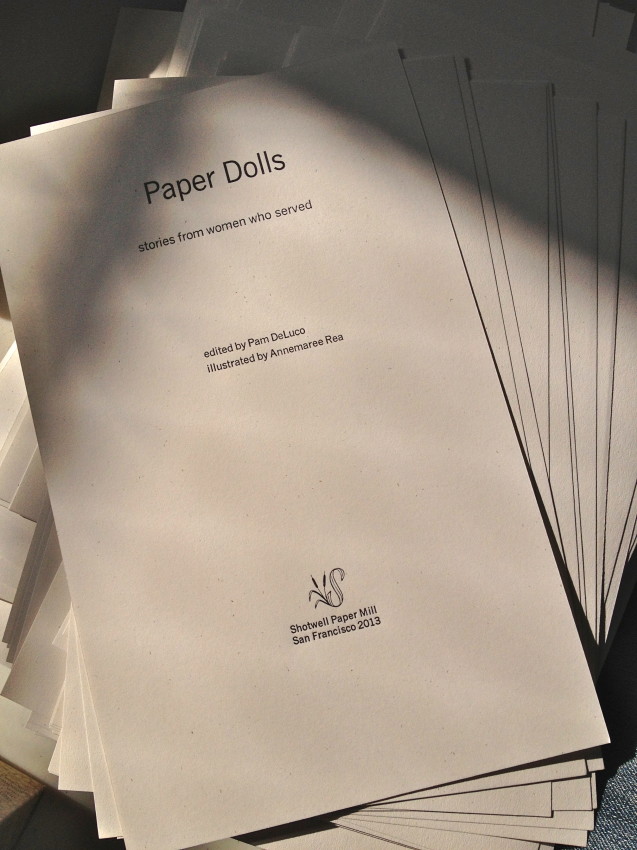

Our first book edition is a Paper Doll book in collaboration with women veterans. The women sent us stories told through a part or parts of their military uniform and these items were printed on paper made from military uniforms. But first we had to make the paper.

Contributor, Dottie Guy, works on deconstructing an Air Force uniform.

The first step in papermaking is to liberate the fiber. Many of the contributors donated their own uniforms to make the paper for the book.

The cut up uniforms are put in a Hollander Beater along with water where they are broken down into a pulp.

This blue pulp came from a blend of Navy and U.S. Coast Guard uniforms.

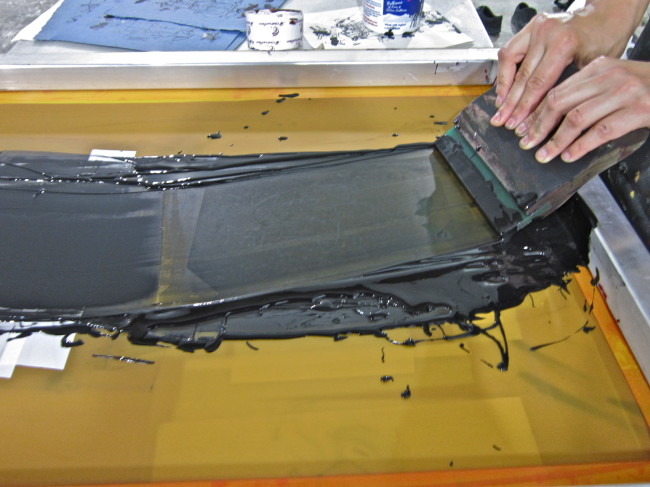

Using a Mould and Deckle, the sheets are formed from the vat of pulp one at a time. In all, we needed over 6000 sheets for the book!

The stack of newly formed sheets are pressed under hydraulic pressure to remove most of the water. The damp sheets are then transferred to a restraint drying system (top right) which has a fan that pulls air through the channels (bottom right). It takes about a day to dry the paper.

|

The dry sheets are put in a standing press to cure. The ratchet straps apply pressure to the stacks of paper which keeps them flat while they cure. We cure our paper for one week to one year or longer. |

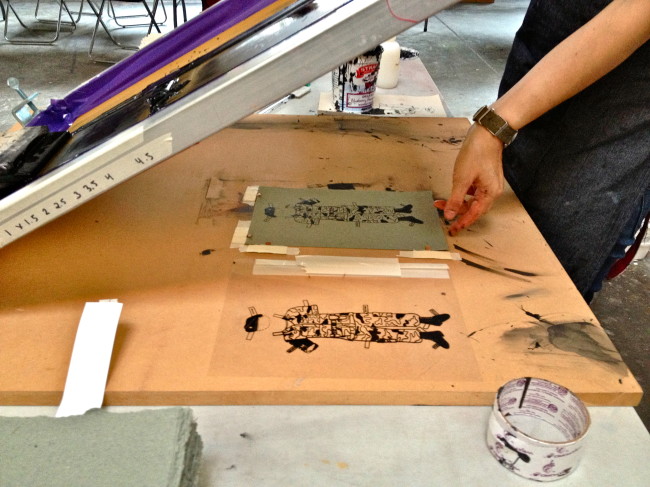

This is Mati, one of the contibutors who lives in Oregon. She spent two weeks with us helping make the book.

Left: Mati’s favorite task was cutting paper using our antique manual guillotine

Right: Mati’s neat stacks of cut paper are ready to be silkscreened.